Electromagnetic Compatibility (EMC)

The development of electronic products must never be at the expense of compliance and reliability. This is why, as a French manufacturer, our responsibility is to ensure that our equipment operates without disrupting its environment and without being disrupted itself. This is where Electromagnetic Compatibility (EMC) truly comes into its own.

What is Electromagnetic Compatibility (EMC)?

EMC ensures that equipment coexists in the same electromagnetic environment.

Indeed, electronics are not perfect. Each component can emit disturbances. Therefore, any material containing electronics can disrupt or be disrupted.

EMC tests verify that equipment complies with current standards before it can be affixed with the CE marking and issued a declaration of EU conformity.

CE marking and the EMC Directive

To sell a product on the European market, it must meet strict specifications determined by notified bodies. Thus, the EMC Directive is one of the main requirements to be met to obtain the CE marking.

Compliance with the EMC Directive is certified in two ways:

- By a certified body that issues a certificate after testing.

- By self-certification, where the company declares the product’s conformity based on the results of tests performed.

For our IFOTEC products, we use several electromagnetic compatibility testing laboratories (including Esynov), which provide us with test reports on the basis of which we self-certify.

Electromagnetic Compatibility (EMC) tests

Emission and immunity

During laboratory tests, we distinguish two major phases:

- Emission tests: These measure the electromagnetic “pollution” that equipment emits, either by conduction (via the electrical network) or by radiation (electromagnetic waves).

- Immunity (or susceptibility) tests: These evaluate the equipment’s ability to withstand external disturbances without performance degradation, such as electrostatic discharges, surge waves, or radiated fields.

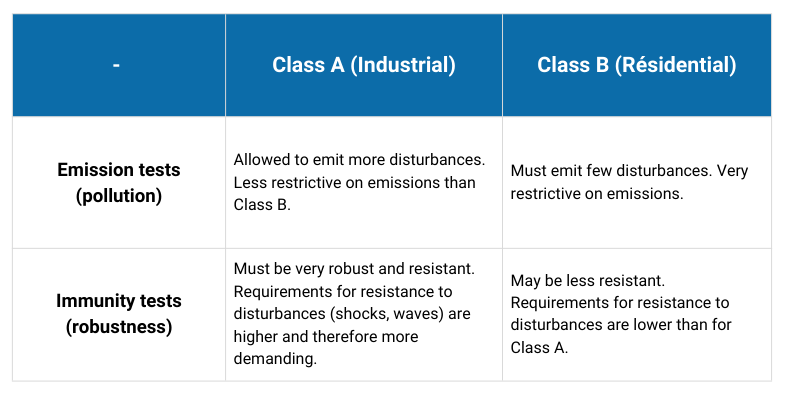

Residential (Class B) or Industrial (Class A) environment?

The level of testing requirements is defined by the product’s final environment.

Fundamental standards and generic standards

To ensure complete qualification, we combine the application of two types of standards.

We use specific fundamental standards for each type of test, such as the IEC 61000-4 series for immunity (e.g., IEC 61000-4-2 for ESD) and standard 55032 for emission measurements.

In addition, we also use generic standards, as our products do not target a specific market (such as railway EN 50121-4 or aeronautical DO-160). They determine performance and requirement thresholds based on the environment:

- 61000-6-1: Immunity for residential environments

- 61000-6-2: Immunity for industrial environments

- 61000-6-3: Emission standard for residential environments

- 61000-6-4: Emission standard for industrial environments

However, some of our equipment may comply with other standards while having passed 61000-6-2 and 61000-6-4 tests. For example, our new Gigabit media converters benefit from additional qualification: alarm systems standard EN 50130-4 and railway standard EN 50121-4.

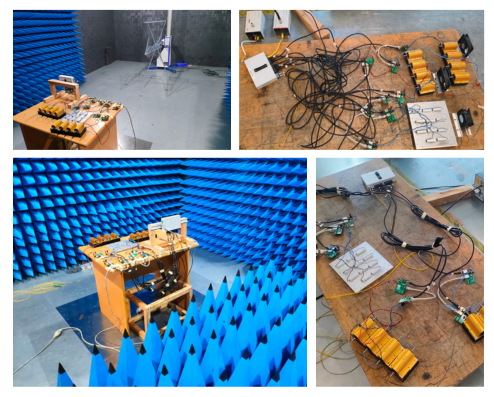

EMC qualification of our INET10X++ switch

As part of the certification of our new manageable 10 Gigabit Ethernet PoE++ switch INet10X++ intended for industrial use, we conducted a series of rigorous tests at the ESYNOV laboratory.

On the left: Immunity and radiated emission test in an anechoic chamber.

On the right: Conducted emission test on the INet10X++.

Our INet10X++ Ethernet switch aimed for industrial standards IEC 61000-6-2 (Immunity) and IEC 61000-6-4 (Emission). Consequently, it complies with all regulatory requirements of Class A, including conducted emission and lightning surges. Thus, we can affirm its reliability in demanding industrial environments.

A guarantee of reliability thanks to EMC tests

Electromagnetic Compatibility is not merely an administrative step, but a critical engineering discipline. It therefore guarantees the reliability, safety, and conformity of equipment.

At IFOTEC, we see EMC as far more than a simple administrative step at the end of a project. We anticipate it from the very beginning of the development cycle. Our approach is proactive:

- We consider the impact of components and apply strict design rules during PCB routing to minimise phenomena that could be disastrous in testing.

- Unlike some structures that separate design and validation, our engineers within our electronic design office are involved upstream and understand the impact of their choices, ensuring a prepared and effective approach.

This proactive approach allows us to subject our equipment to extremely rigorous EMC tests, often exceeding minimal requirements. This level of expertise ensures the quality and performance of our equipment for all environments (residential or industrial).